NET CYBER HEADS: Technical specifications and integration guide

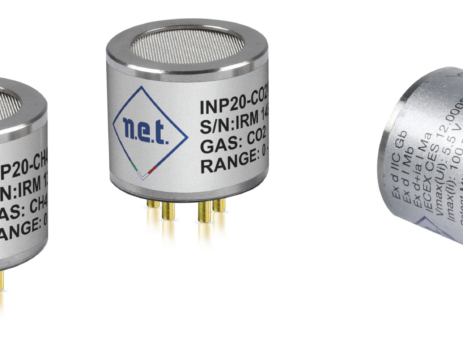

NET Cyber Heads are ready-to-use enclosures that combine Gas sensors and signal-processing electronics. These units function as either integrated components for Gas detectors or as standalone field devices. Applications for Manufacturers and Integrators The Cyber Head series is engineered for OEMs and system integrators seeking to streamline product development. Utilizing these pre-certified units eliminates the need for: In-house sensor development or sourcing. Designing firmware...