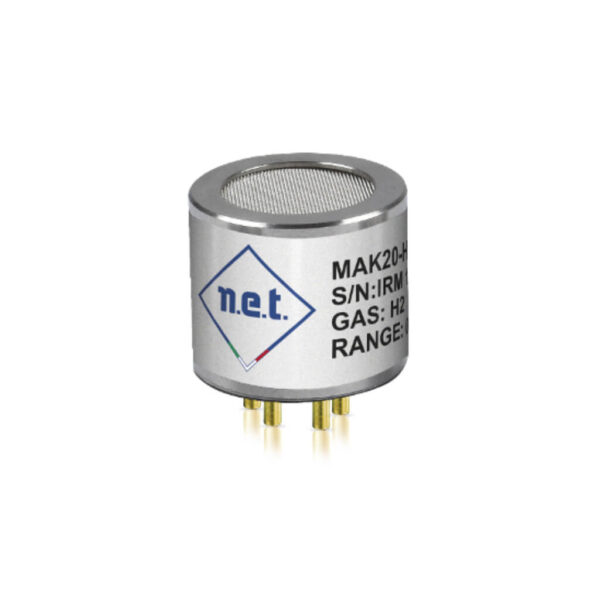

Advantages of our MAK 20mm Intelligent Thermal Conductivity Gas Sensor:

- Individual calibration and testing, for measurements you can trust

- Extended temperature range (-40 °C to +85 °C), for use in any environment

- Active Environmental compensation (Temperature, RH, Pressure)

- Internal microprocessor, for advanced signal processing

- Standard industrial size, to fit existing detectors

- Low power consumption

- Fast T90 response time (< 20 s), for critical and life-saving applications

- Outstanding long-term stability of 0.1 % F.S./year

- Broadest available ranges, up to 100 % volume

- ModBus or P2P digital communication, for ease of integration

- Signal versatility: voltage and optional bridge or pellistor output

- Solid, rugged construction with stainless steel enclosure

- Standard industrial accepted negative or positive pinout

With the application of MEMS (Micro Electronic Mechanical Systems) technology, NET is making the power of thermal conductivity gas sensors available for the broadest range of Hydrogen detection applications. By employing very repeatable, high-volume CMOS (Complementary metal-oxide-semiconductor) MEMS technology, the new NET KATHAROMETER GAS TECHNOLOGY is lowering production costs and the typically high power consumption of thermal conductivity gas sensors.

MAK sensors detect hydrogen concentrations in the air by measuring the change in thermal conductivity of the gas mixture. Thermal conductivity sensors are most effective when detecting gasses with low molecular weight, which correspond to greater thermal conductivity. Hydrogen possesses the highest thermal conductivity of all known gasses.

The NET MAK Intelligent hydrogen sensor features a standard 4-series size and pinout, with negative or positive pinout and voltage or optional bridge output – dramatically reducing the integration on existing detectors and platforms developed for classic NDIR sensors.

Unlike catalytic bead sensors, NET MAK sensors covers the broadest range of detection, working well from ppm level, up until 100 % volume. This is because they can operate without the presence of Oxygen. They also provide far better long-term stability than sensors that are triggered by chemical reactions that eventually cause the sensor to degrade. Thermal conductivity gas sensors, in fact, do not involve physical or chemical changes in the sensor. This, coupled with outstanding resistance to poisoning, results in far greater operating lives than for traditional technologies.

NET MAK MEMS-membrane-based sensor offers a far greater resistance to mechanical shocks when compared to catalytic or traditional thermal conductivity sensors.

Another key factor is the fast response time of the sensor (< 1.4 s), the only limiting factor being the time required for changes in the measurement resistor.

| Detectable gases - MAK 20mm Intelligent Sensor: | |

|---|---|

| Hydrogen |

- Download Center