The science of Gas Detection: a deep dive into Thermal Conductivity and Katharometer

In the field of industrial safety, Gas detection is often synonymous with chemical sensors. However, as industries push toward the Hydrogen economy, traditional chemical and catalytic methods reach their physical limits.

The alternative is a measurement principle based on pure physics: Thermal Conductivity Gas Sensing, also known as Katharometer.

Understanding the Physical Principle

Thermal Conductivity is an intrinsic physical property of a Gas, representing its ability to conduct heat. In a vacuum or a static environment, different Gases transfer thermal energy at different rates based on their molecular structure.

The Katharometer Mechanism

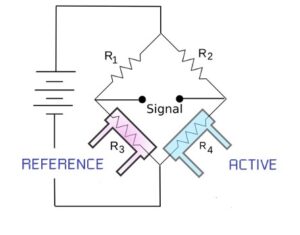

A Katharometer operates by comparing the heat transfer of a target Gas and a known reference. This is achieved through a high-precision Wheatstone bridge configuration:

- Heat Dissipation: A sensing element (typically a filament or a specialised die) is heated to a constant temperature.

- The Differential Measurement: The sensor utilizes two elements. The Reference Element is sealed in a stable Gas (usually dry air), while the Active Element is exposed to the process Gas.

- The Resistance Shift: When a Gas with a high thermal conductivity—such as Hydrogen (H₂) or Helium (He) replaces the air around the active element, it transfers more heat. This cooling effect changes the element’s electrical resistance.

- Signal Output: The resulting voltage imbalance in the bridge is processed to provide a concentration reading, ranging from parts-per-million (ppm) up to 100% volume.

- Why is Thermal Conductivity superior for high-concentration Hydrogen?

Hydrogen has exceptionally high thermal conductivity. This creates a significant “thermal signature” that is easily distinguishable from air. Unlike catalytic pellistors, which can “burn out” or deplete their catalyst in high-concentration environments, a thermal conductivity sensor like the MAK remains stable and accurate up to 100% H₂ concentration.

- Can this technology operate in anaerobic (Oxygen-free) conditions?

Yes. This is a primary technical advantage. Catalytic and electrochemical sensors require a chemical reaction, which necessitates the presence of oxygen while Thermal Conductivity is a purely physical measurement of heat transfer. NET’s new MAK sensor is based exactly on thermal conductivity. As it is a physical operating principle, the sensor works in inert environments or in the total absence of oxygen. Thanks to their ability to operate without oxygen, they work effectively from ppm levels up to volume % ranges.

- How does the technology eliminate the risk of “Poisoning”?

In many industrial settings, silicones, lead, or sulfur compounds can “poison” a catalytic sensor, rendering it useless. Because a Katharometer does not use a catalyst or any sacrificial material, it is intrinsically immune to chemical poisoning.

NET’s new MAK sensor does not use a catalytic combustion process, substances commonly lethal to pellistors, cannot adhere to or degrade the active part of the MEMS element. This translates to an extremely long operational life and a drastic reduction in maintenance costs.

- How is the “Thermal Drift” managed?

Thermal conductivity is naturally sensitive to ambient temperature and pressure changes. To ensure “technically impeccable” accuracy, the MAK incorporates an on-board microprocessor. This allows for active real-time environmental compensation, correcting for temperature fluctuations between -40 °C and +60 °C and ensuring a long-term stability of 0.1% F.S./year.

Modern industrial requirements for stability and integration have led to the development of advanced solutions like the N.E.T. MAK series.

By exploiting the predictable physical behaviour of gases, Thermal Conductivity offers a stable, highly accurate and low-maintenance solution for the most demanding industrial environments.

To receive technical documentation or customized support reach out to info@nenvitech.com