Understanding ATEX Directives: Workplace and Equipment Safety Standards

What does ATEX stand for?

The term ATEX is derived from the French title of the 94/9/EC directive: Appareils destinés à être utilisés en ATmosphères EXplosibles. It encompasses two European Directives that establish minimum safety requirements for equipment and workplaces within explosive atmospheres.

What are the two primary ATEX Directives?

ATEX legislation is divided into two specific areas of responsibility:

- Directive 1999/92/EC (Workplace Directive): This concerns the Employer. It regulates the classification of explosive atmospheres into area classes based on the likelihood and persistence of an explosive risk.

- Directive 2014/34/EU (Equipment Directive): This concerns the Manufacturer. It provides a harmonized set of standards for equipment and protective systems intended for use in potentially explosive atmospheres across EU member states.

How are ATEX products identified?

ATEX certified products feature a specific marking anatomy. This marking indicates the product’s type of protection and its suitability for specific hazardous areas.

How is an ATEX product certificate issued?

To issue an ATEX product certificate, a manufacturer must hold a valid Quality Assurance Notification (QAN). This involves:

- Continuous Monitoring: A notified body monitors Ex product-related systems and processes.

- Periodic Audits: Inspections of the production site, manufacturing records, and equipment specifications are conducted typically every 12 to 18 months.

- Regulatory Compliance: The manufacturer must comply with the appropriate Annex(es) of the Directive, based on the equipment designation (zone), production volume, and the presence of an ISO 9001 compliant system.

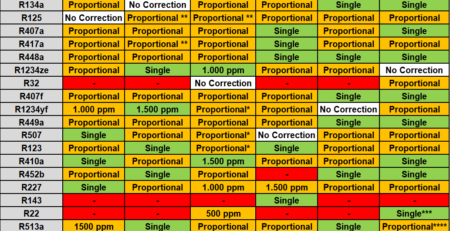

Which N.E.T. products are ATEX certified?

Our range of certified equipment includes the:

In addition to Essential Safety Requirements (ESR), Full Cyber Head and XIN Head products are tested for performance according to EN/IEC 60079-29-1:2016.

How does N.E.T. ensure quality standards?

We undergo periodic inspections to verify our quality assurance system. We believe that the overall quality of the processes within an organisation is directly reflected in its products. Due to this, we maintain high certification standards issued by renowned notified bodies.

Technical information: to receive technical documentation or customized support reach out to info@nenvitech.com