Hydrogen Monitoring: Achieving Integrated Safety with the new MAK sensors

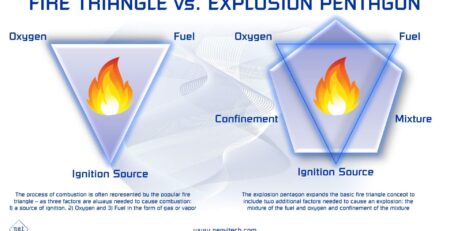

Hydrogen is regarded as the future of clean energy, but its use requires high safety standards. As a highly flammable, odourless gas with an extremely high dispersion rate, constant monitoring is not only an operational necessity but also a critical requirement for every infrastructure, from electrolyzers to refuelling stations.

In this scenario, traditional detection technologies, such as pellistors and electrochemical cells, often show structural limits:

- The need for Oxygen to function

- Vulnerability to chemical poisoning

- The requirement for frequent maintenance.

We collected some frequently asked questions regarding the implementation of the new MAK sensor.

Is it possible to detect Hydrogen in the absence of Oxygen?

Yes. Unlike catalytic sensors (pellistors) and electrochemical cells, which require oxygen for the chemical reaction to occur, the new MAK sensor is based on thermal conductivity. Since it is a physical operating principle, the sensor functions in inert environments or in the total absence of Oxygen, covering the entire detection range from ppm up to 100% by volume.

How does the sensor handle poisoning from chemical agents?

The MAK sensor is intrinsically immune to poisoning. Since it does not use a catalytic combustion process, substances such as silicones or silanes — commonly lethal to pellistors — cannot adhere to or degrade the active part of the MEMS element. This translates to an extremely long operational life and a drastic reduction in maintenance costs.

Which options are available for integration into existing systems?

MAK is designed for maximum flexibility. It supports digital communication via UART Modbus protocol and also offers a standard voltage output (0.4-2V). The standard version comes with a 20 mm industrial pinout (either positive or negative), thus adapting to most existing detection platforms. Furthermore, to facilitate retrofitting, it is also available in bridge configurations. This layout is exactly the same as the one currently in use on our NDIR sensors, which will allow current customers to easily integrate MAK in their systems with no design overhauls.

How can precision be ensured in variable environmental conditions?

Every MAK sensor includes an internal microprocessor which applies active environmental compensation. The device automatically corrects readings based on variations in temperature (with an operating range from -40 °C to +60 °C), relative humidity, and atmospheric pressure, ensuring reliable measurements even in outdoor industrial environments or those subject to climatic stress.

What are the advantages in terms of maintenance and stability?

The absence of chemical reactions gives MAK superior long-term stability, rated at 0.1% F.S./year. This means that the need for recalibration is minimal, guaranteeing a significantly lower Total Cost of Ownership (TCO) compared to technologies that require annual replacements or frequent recalibration due to signal drift.

The transition to a Hydrogen-based economy requires monitoring infrastructures capable of addressing large-scale production, storage, and distribution challenges. MEMS thermal conductivity technology stands as a solid technological foundation to support this transition in the safest way possible.

The MAK series is a technological response to the complexities of the Hydrogen economy.